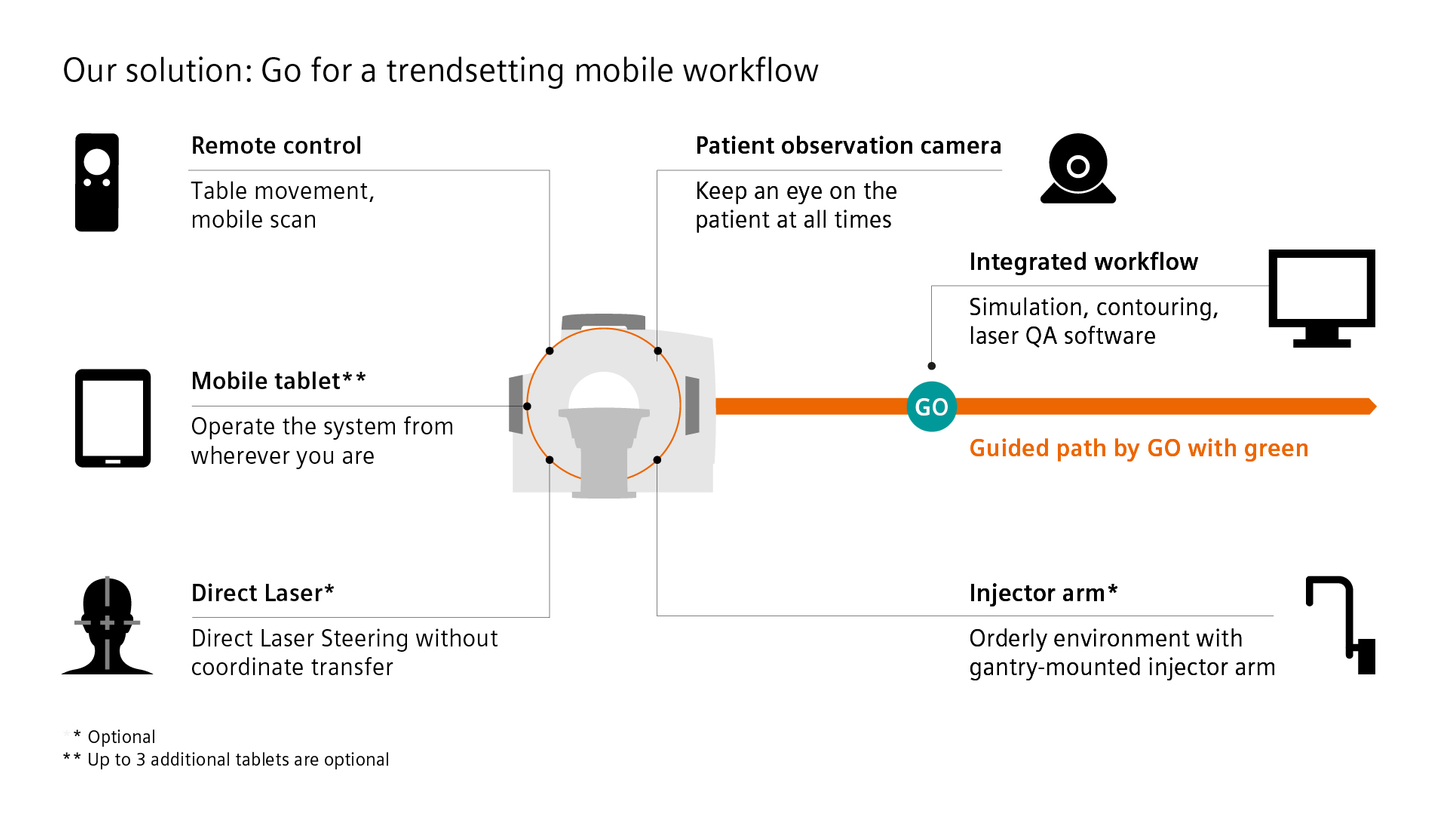

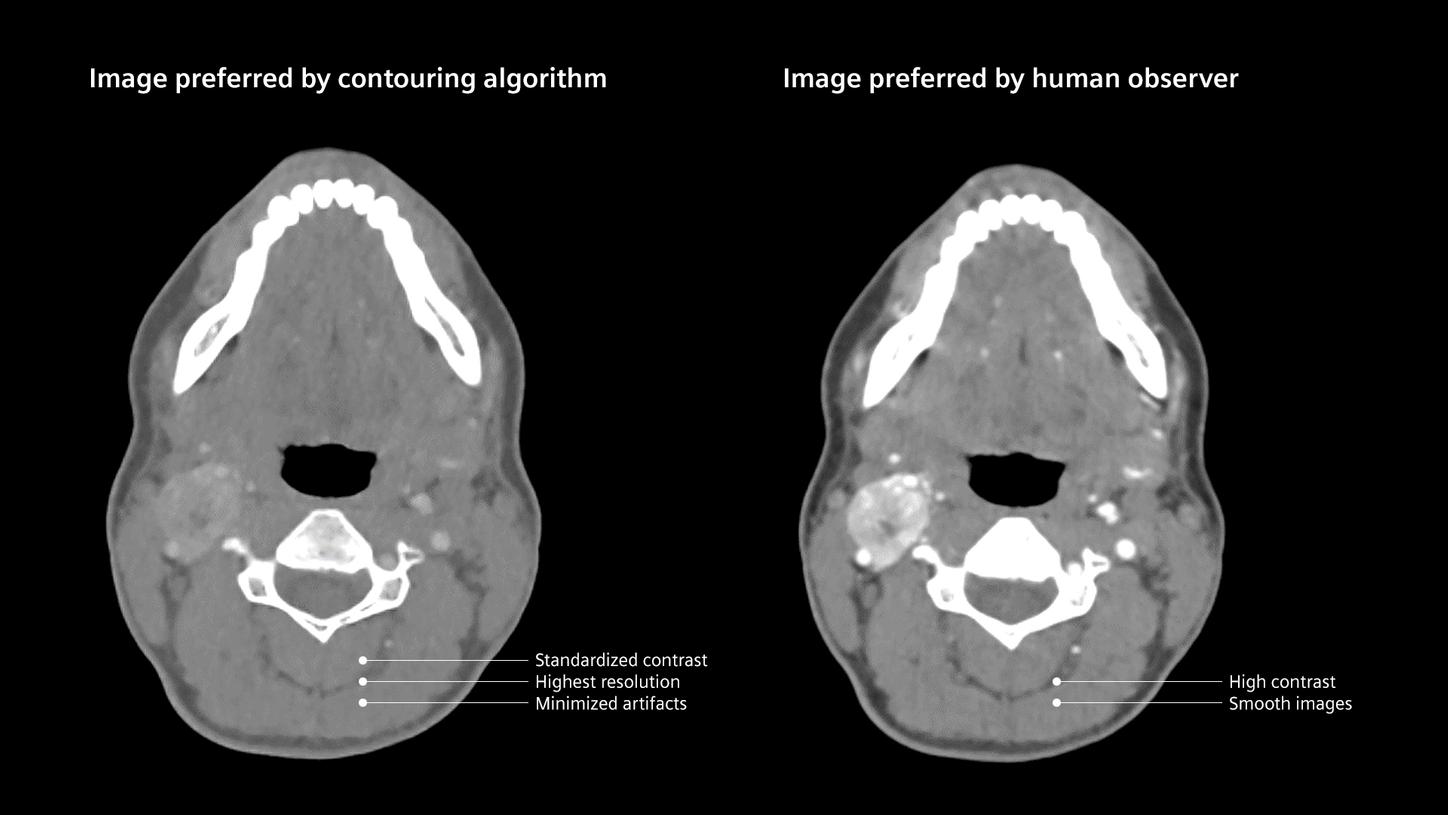

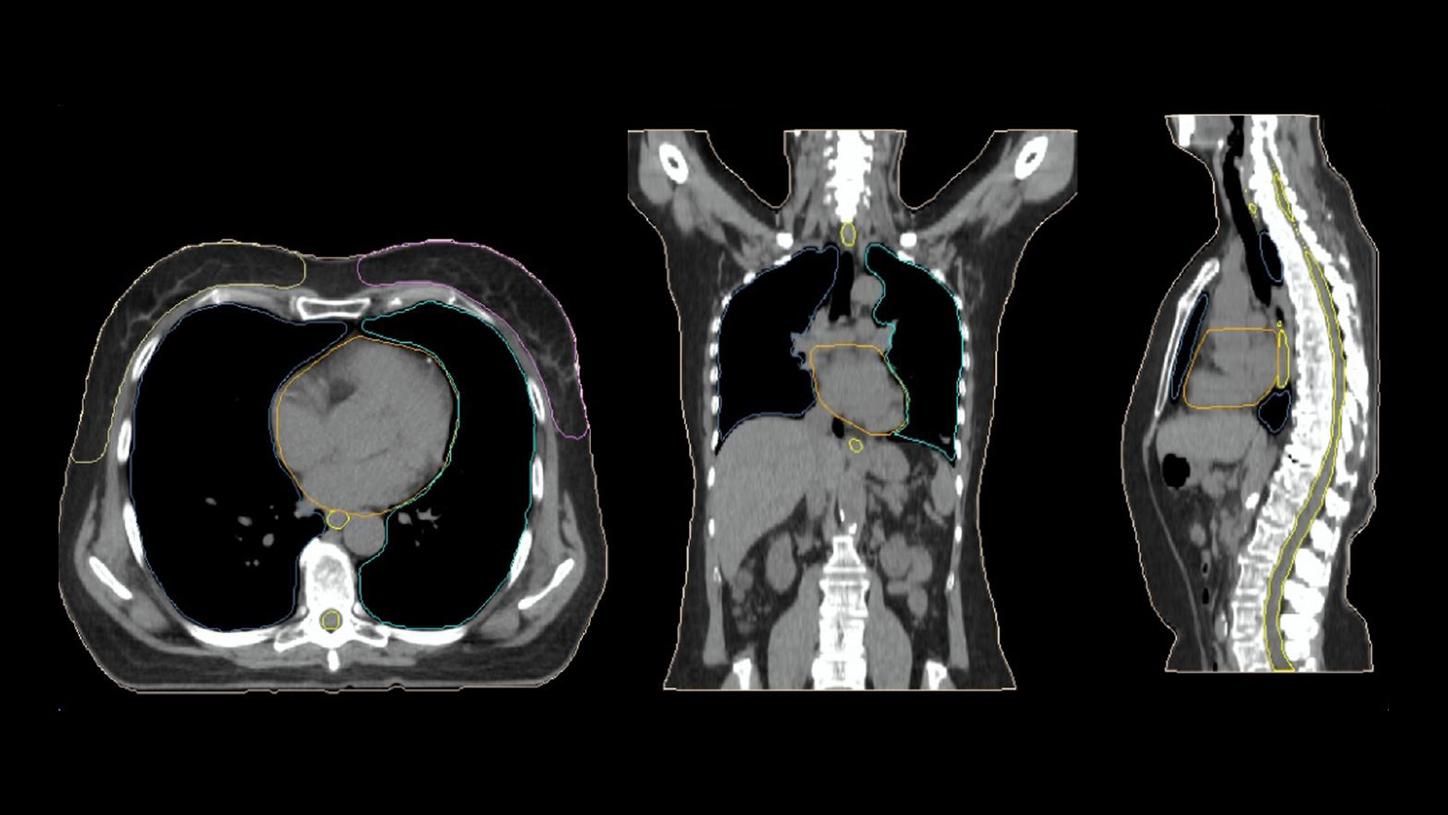

SOMATOM go.Sim is a highly flexible, intuitive CT simulator. With fully integrated hardware and software tailored specifically to your requirements, it increases certainty and reduces the likelihood of errors. It also features advanced algorithms, AI-powered organ-at-risk (OAR) autocontouring, and excellent soft-tissue contrast potentially decreasing target margins. What’s more, it is designed to care for both patients and users – with a calming environment, a simple operating concept, and a single vendor service contract.

SOMATOM go.Sim can increase workforce productivity and optimize clinical operations. It helps you get the full picture faster so you can spend less time managing CT simulation and more time focusing on patients.